Application of Polyurethane Timing Belts in Photovoltaic Basket Machine Conveyor Lines

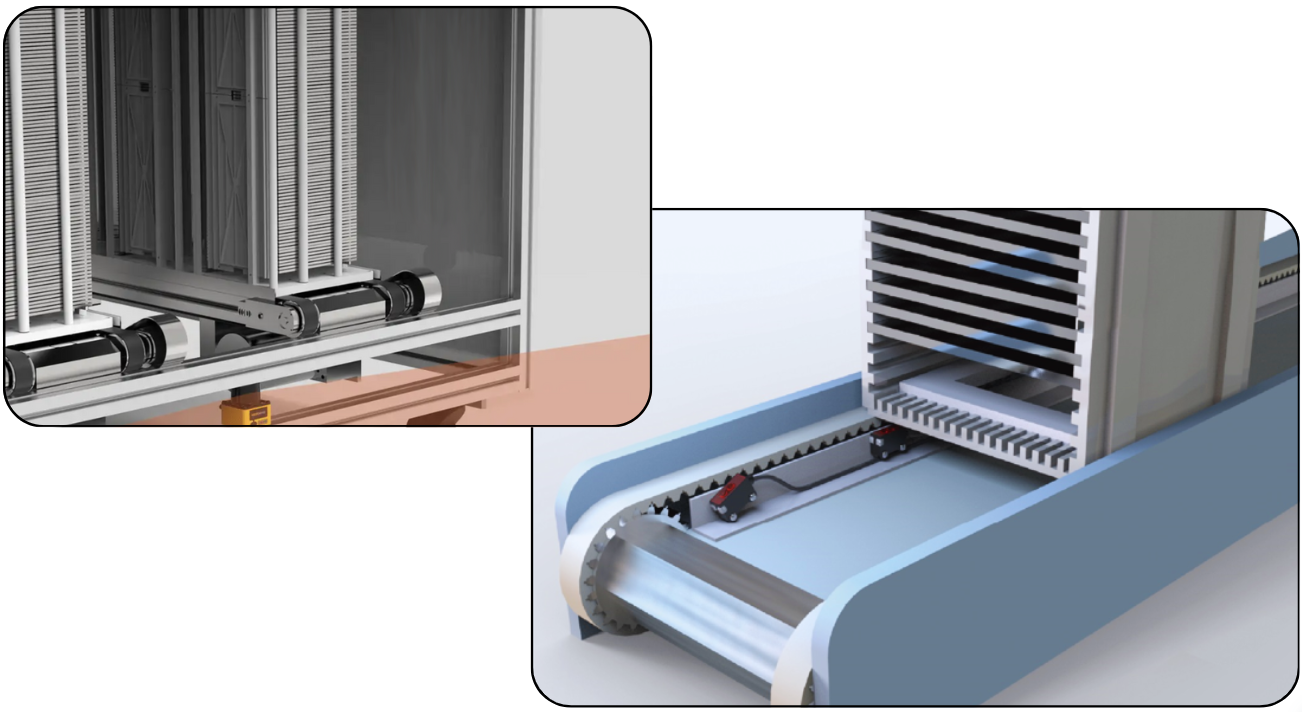

The photovoltaic flower basket machine, also known as the photovoltaic module framing machine or photovoltaic module basket framing machine, is an essential piece of equipment in the photovoltaic industry. These machines are used to place photovoltaic modules or solar cells into specific basket frames, facilitating their transportation, storage, and installation. They are indispensable in the production of photovoltaic panels, ensuring efficient handling and processing of photovoltaic cells and modules, effectively improving production efficiency, reducing manual operation errors, and ensuring the integrity and safety of photovoltaic modules. A key component of this system is the conveyor belt, which plays a crucial role in the overall operation. The following is an overview of the application and importance of the belt in the photovoltaic flower basket machine conveyor system:

1、Material Handling

2、Efficiency and Speed

3、Precision and Accuracy

|   |

4、Durability and Maintenance

- The durability of conveyor belts is equally crucial for the continuous operation of photovoltaic basket machines. The belts are designed to withstand the harsh conditions of the production environment, including exposure to chemicals, extreme temperatures, and mechanical wear.

- Belt maintenance is simplified to minimize downtime. Regular inspections, timely replacements, and proper tensioning are key practices to ensure the longevity and reliability of the belts.

5、Customization

- Conveyor belts can be customized to meet the specific requirements of photovoltaic basket machines. This includes variations in belt width, length, thickness, and surface texture to accommodate different sizes and types of photovoltaic cells.

- Special features can be incorporated into the belt design, such as antistatic properties, heat resistance, and enhanced grip, to address the unique challenges of the photovoltaic production process.

6、Integration with Automation

- Conveyor systems are often integrated with automation technologies such as robotic arms and sensors to further streamline the production process. Belts play a crucial role in ensuring precise movement and positioning required for automated operations.

- Feedback systems provide real-time data on belt performance, allowing for timely adjustments and improvements to optimize production workflows.

The application of conveyor belts in photovoltaic basket machines is crucial for ensuring the efficiency, precision, and reliability of solar panel production. By providing smooth material handling, increasing production speeds, maintaining precise positioning, and integrating with advanced automation technologies, conveyor belts play a critical role in the success of the photovoltaic manufacturing process.