Development Trend Of Medical Apparatus Synchronous Belts Market

1. Market Insights

Medical equipment transmission belts play a crucial role in medical devices, and the market is expanding continuously with the development of medical technology and increasing demand. Here are some insights into the medical equipment transmission belt market: Market Size: It is projected that by 2024, the global market for medical equipment transmission belts will reach $1.5 billion, with an annual growth rate of approximately 5.2%. This growth is driven primarily by an aging population, rising demand for medical equipment, and technological advancements. Regional Distribution: North America, Europe, and the Asia-Pacific region are the primary markets. North America holds the largest market share due to advanced medical technology and a large healthcare market. The Asia-Pacific region is the fastest-growing area due to rapid growth in healthcare demand. Primary Applications: Medical equipment transmission belts are widely used in various medical devices, including CT scanners, MRI machines, automated laboratory equipment, and surgical robots. These devices have stringent requirements for belt precision, reliability, and durability.

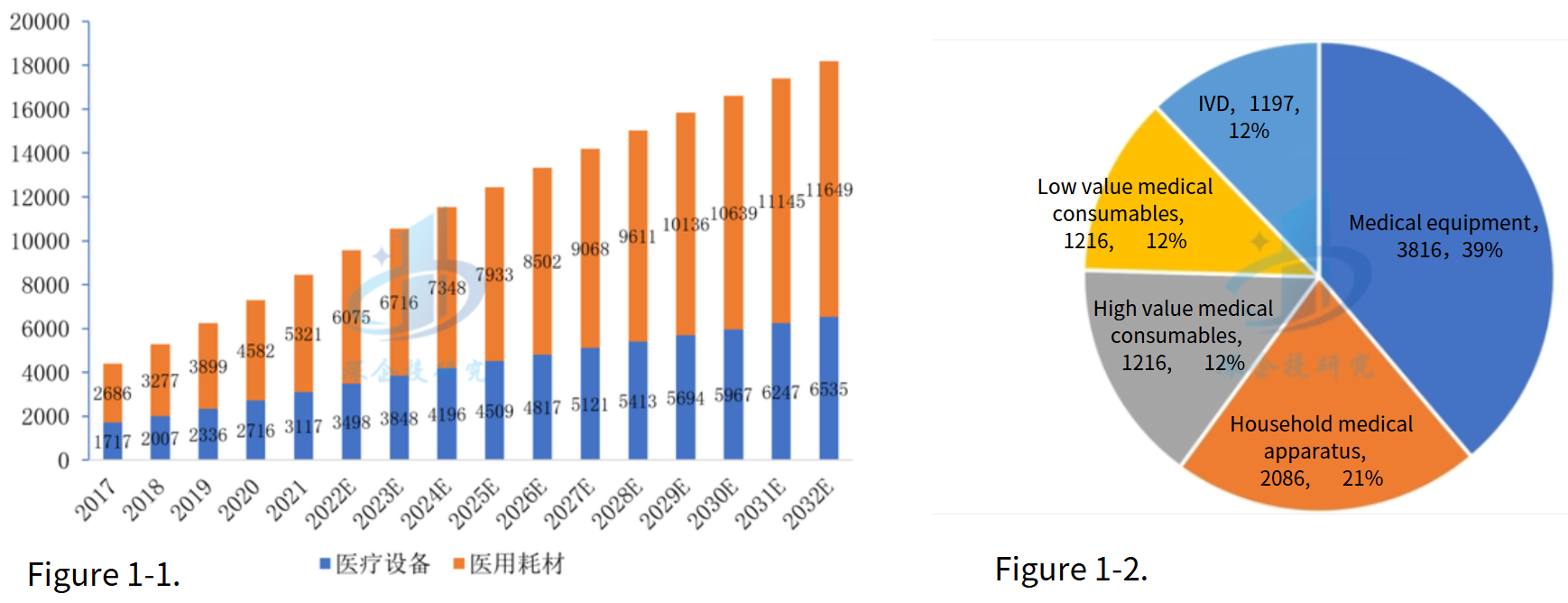

| China has become the world's second-largest medical device market. The market size of China's medical devices accounts for approximately one-fourth of the global market, second only to the United States (31%). According to Frost & Sullivan, it is estimated that the market size of China's medical devices will reach about 960 billion yuan in 2022, with a compound annual growth rate of approximately 17.5% from 2015 to 2022, significantly higher than the global average. The market size of China's medical devices is expected to reach 1.24 trillion yuan by 2025, with a compound annual growth rate of 10.2% from 2021 to 2025. By 2032, it is expected to increase to 1.82 trillion yuan, with a compound annual growth rate of 5.6% from 2025 to 2032. as shown in Figure 1-1. According to Eshare Medical Devices, in 2022, the major sectors of China's medical device market include medical devices, home medical devices, high-value medical consumables, low-value medical consumables, and in vitro diagnostics, accounting for 39%, 21%, 15%, 12%, and 12%, respectively, as shown in Figure 1-2. |  |

The Yangtze River Delta, Pearl River Delta, and Bohai Rim region are the primary clusters of medical device manufacturing enterprises in China. By the end of 2022, the Yangtze River Delta region, comprising four provinces and municipalities, hosted 9,271 medical device manufacturing enterprises, accounting for 28.4% of the national total. The Bohai Rim region (Beijing-Tianjin-Hebei-Shandong-Liaoning) had 8,582 medical device manufacturing enterprises, accounting for 26.3% nationwide. Guangdong Province led all provinces with 4,968 medical device manufacturing enterprises, representing 15.2% of the national total. Together, these three regions account for approximately 70% of the national total. In terms of distribution among different categories of medical device manufacturing enterprises, the Yangtze River Delta accounts for 29.2%, while the Bohai Rim and Guangdong Province account for 20.0% and 16.5%, respectively, collectively representing about two-thirds of the national total. Specifically, the Yangtze River Delta region holds a significant advantage, comprising approximately 40% of the national total in category two and three medical device manufacturing enterprises, indicating a substantial demand for synchronous belts in the medical device sector.

2. The Use Of HERZ Synchronous Belts In Related Medical Equipment

Synchronous belts play a crucial role in various medical devices:1. Imaging Equipment: Such as CT and MRI scanners, synchronous belts ensure synchronous operation of scanning components, enhancing image clarity and accuracy. CT Equipment: CT scanners generate detailed cross-sectional images using X-rays and computer processing. During scanning, the X-ray tube and detectors rotate around the patient with high precision and synchronization facilitated by synchronous belt drive systems, ensuring synchronized motion to improve image resolution and accuracy. MRI Equipment: MRI scanners use strong magnetic fields and radio frequency pulses to create detailed images of the body's interior. Components like coils and magnets require synchronized movement for precise positioning and motion, critical for maintaining image quality by minimizing vibrations or misalignment. 2. Dental Equipment: Such as dental drills and grinding devices, synchronous belt drives offer smooth and controllable operations, reducing patient discomfort. Dental Drills: These devices require high-speed rotation and precise control during drilling and shaping. Synchronous belt drive systems provide smooth, backlash-free power transmission, ensuring stability and precision even at high speeds, reducing vibrations and noise for improved drilling accuracy and patient comfort. Grinding Equipment: Used in tooth reshaping and polishing, grinding equipment demands high-precision grinding operations. Synchronous belt drive systems deliver smooth power output, ensuring uniform and smooth grinding processes, thereby preventing tooth damage or treatment failure due to equipment vibration. 3. Surgical Robots: Utilized in minimally invasive and complex reconstructive surgeries, synchronous belt drive systems provide highly precise motion control. In microsurgical procedures, where precise movements within millimeters or smaller ranges are required, synchronous belts ensure stable and accurate movement, crucial for maintaining surgical precision and consistency. 4. Medical Reagent Testing Equipment: |  |

Fully Automated Blood Analyzers:

Synchronous belts are used for precise sample transmission within the equipment. From the sample loading area to various analysis modules, synchronous belts ensure samples reach designated positions accurately and within specified times. This high-precision transmission is essential for ensuring the accuracy of sample analysis results.

3.Characteristics Of Synchronous Belts In The Medical Industry:

In the medical industry, synchronous belts, particularly those made from polyurethane, are preferred for their transmission and conveying capabilities due to several notable characteristics:

1. High Transmission Efficiency: Polyurethane synchronous belts have low friction losses and high transmission efficiency, effectively converting input power.

2. High Transmission Accuracy: Polyurethane synchronous belts offer excellent transmission accuracy and stability, enabling precise position control.

3. High Load Capacity: Polyurethane synchronous belts exhibit high tensile strength and load-bearing capacity, capable of handling large loads.

4. Long Service Life: Polyurethane materials are wear-resistant and fatigue-resistant, contributing to the prolonged service life of synchronous belts.

5. Low Noise and Vibration: Due to precise transmission capabilities, polyurethane synchronous belts operate with low noise and vibration levels, suitable for applications sensitive to noise and vibration.

6. Environmental Adaptability: Polyurethane synchronous belts demonstrate good resistance to chemicals such as acids and alkalis, displaying some environmental adaptability. However, they are sensitive to environmental conditions such as temperature, humidity, and chemical substances.

4. Technology Trends

As medical technology advances, synchronous belts in medical equipment transmission are continuously innovating to meet increasingly stringent application requirements. Here are the current key technological trends:

Material Upgrades: Modern synchronous belts are evolving towards materials with higher strength and wear resistance to enhance their performance under high loads and prolonged operation.

Enhanced Precision: Improvements in tooth profile design and manufacturing processes enable synchronous belts to be more precise in medical equipment applications, reducing errors and failure rates.

Smart Applications: With the development of the Internet of Things (IoT) and smart technologies, smart synchronous belts are being applied in medical devices to enable real-time monitoring and preventive maintenance.

The application of synchronous belts in the field of medical devices encompasses various equipment, including but not limited to imaging devices, monitoring equipment, surgical instruments, and laser equipment. Through precise transmission and control functions, they support the advancement and innovation of medical technology, providing healthcare professionals with a safer and more effective working environment and tools. In summary, the widespread use of synchronous belts in the medical device sector not only enhances equipment performance and accuracy but also significantly supports technological advancements and service quality in the healthcare industry.