Synchronization belt installation and precautions

Application Scenarios

-

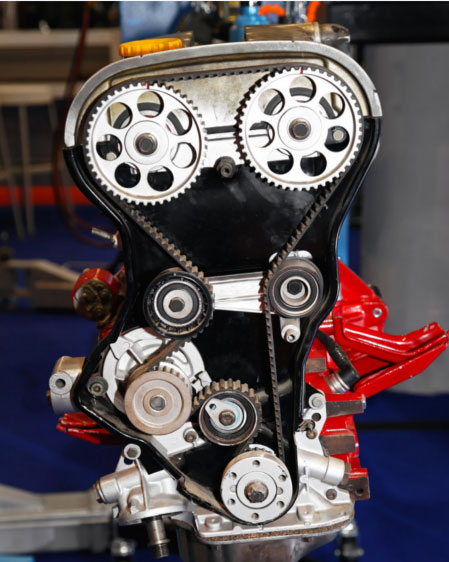

Automobile (engine)

From the crank shaft in the lower part of the engine to the camshaft in the upper part, the CAM position is controlled by the number of teeth of the belt wheel, and the action of suction, ignition and exhaust is controlled.

-

Electronics industry

Circuit board/panel production line long span transfer.Horizontal transmission, light product, slow speed, small turning radius.

Precautions for installing the synchronization belt

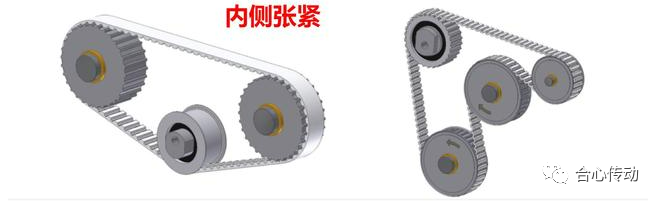

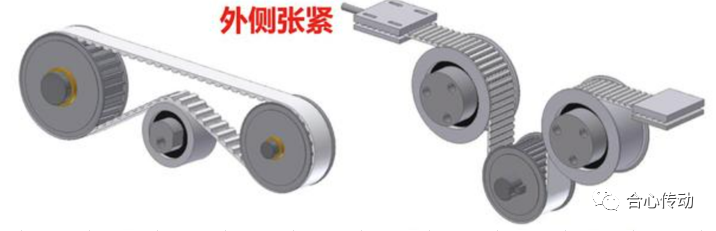

1. When installing the synchronization belt, if the center distance of the two belts can be moved, the center distance of the belt must be shortened first, and then the center distance is reset after the synchronization belt is installed. If there is a tension wheel, first loosen the tension wheel, then install the synchronization belt, and then install the tension wheel.

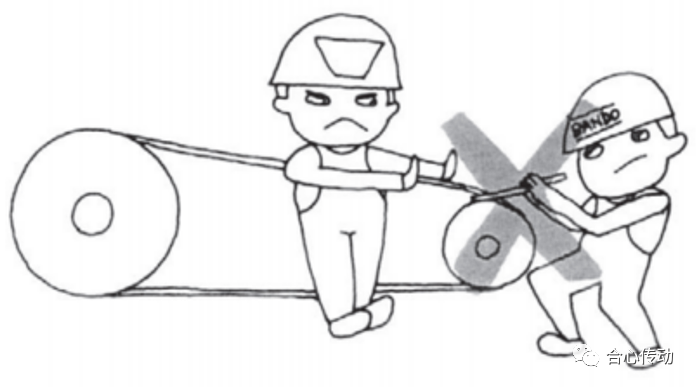

2. When installing the synchronization belt to the belt wheel, remember not to exert too much force, or use a screwdriver to pry the synchronization belt hard to prevent the tensile layer in the synchronization belt from causing the appearance of invisible breaking. When designing the belt wheel, it is best to choose a structure that the two axes can move close to each other, if the structure is not allowed, it is best to install the synchronization belt and the belt wheel together on the corresponding shaft.

3, control the appropriate initial tension force.

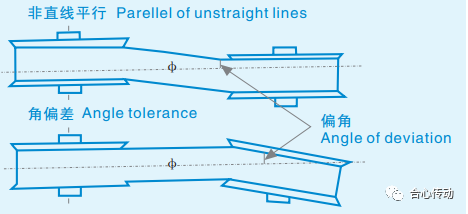

4, synchronous belt transmission, the parallelism of the axis of the two belts is relatively high, otherwise the synchronous belt will produce deviation in the work, and even jump out of the belt wheel. Axis is not parallel will also cause uneven pressure, so that the early wear of the teeth.

5. The frame supporting the belt wheel must have sufficient stiffness, otherwise the belt wheel will cause the two axes to be not parallel when the code lock is running.

Synchronization belt and pulley maintenance

1. The synchronous belt should not be twisted and sharply bent

2. Synchronous belt in the storage and transportation process, should avoid direct sunlight, rain and snow immersion; Prevent contact with acids, halides, organic solvents, water vapor and other substances that affect product performance.

3. The synchronous belt should be stored at normal temperature, the general temperature is -20~50°C, and at least one meter away from the heat source.

4. During storage, it is necessary to prevent excessive weight and deformation, not folding and stacking, not placing the belt directly on the ground, and hanging the belt on the shelf or flat on the shelf.

5. The finished pulley should be purchased and transported in a dry and ventilated environment, and the finished pulley should be treated with rust prevention.

6. The belt transmission device should be protected, and ensure ventilation and blowdown.