Timing Belts, The Underrated Component Of Robots

In the process of modern industrial automation, robotic technology continues to innovate, becoming a key factor in enhancing production efficiency and precision across various industries. As the application of robots becomes more widespread, the importance of transmission systems is increasingly highlighted. However, among the many complex transmission systems, one component is often underrated—the timing belts.

This article will delve into the importance of timing belts in robotics and, in conjunction with the professional manufacturing advantages of Zhejiang HERZ Transmission System Co., Ltd., reveal the irreplaceable role of timing belts in robot joint drives, motion mechanisms, and end-effector design.

First, We Need To Uderstand What Belt Drive Is.

Belt drive is a mechanical transmission method that utilizes a flexible belt to transfer power between pulleys. It is widely used in industrial applications due to its advantages of simple structure, smooth transmission, and low noise. Belt drives mainly include flat belt drive, V-belt drive, and synchronous belt drive. Among them, timing belts drive has been widely applied in the field of robotics due to its precise transmission characteristics.

Three Major Characteristics Of Robots

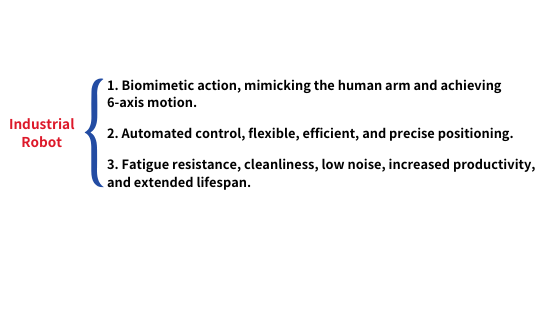

Belt drive is a mechanical transmission method that utilizes a flexible belt to transfer power between pulleys. It is widely used in industrial applications due to its advantages of simple structure,

smooth transmission, and low noise. Belt drives mainly include flat belt drive, V-belt drive, and synchronous belt drive. Among them, synchronous belt drive has been widely applied in the field

of robotics due to its precise transmission characteristics.

Three Major Characteristics Of Robots

The Importance Of Timing Belts In Robots:

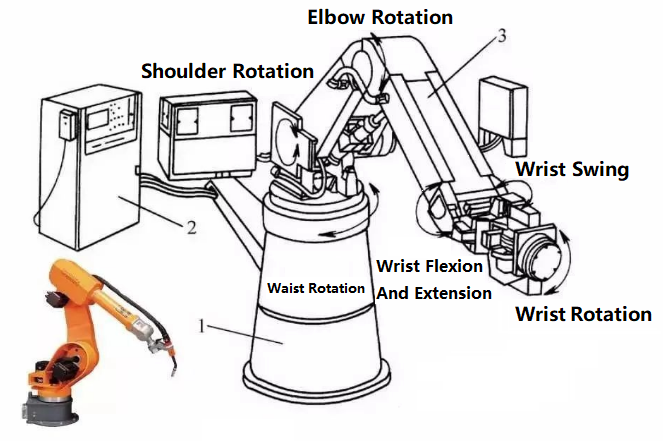

High-precision transmission in joint drive:achieving biomimetic motion The precise movement of robot joints relies on a high-precision transmission system. Timing belts transmit power through toothed engagement, ensuring a high degree of transmission ratio accuracy, enabling robot joints to maintain precise position and angle control in complex movements. This is particularly important for industrial robots in applications with high requirements such as manufacturing and assembly. |  |

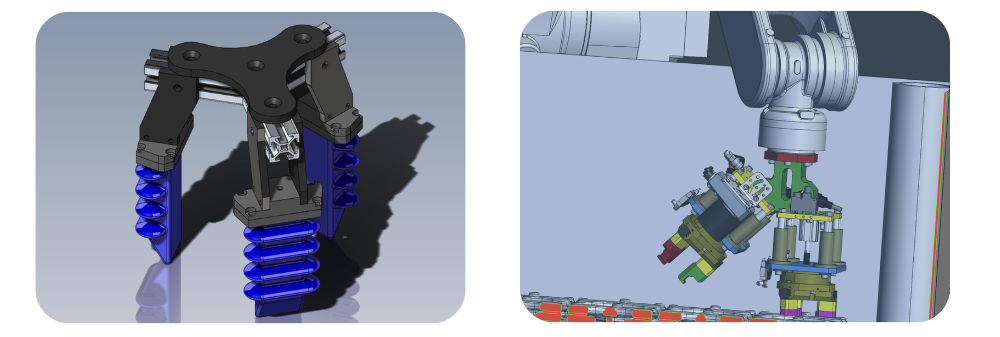

Flexibility in end effector design:automation control The design flexibility of timing belts drive systems enables their wide application in the design of robot end effectors. Whether for linear or complex rotational movements, synchronous belts can easily handle them. Such design flexibility not only enhances the adaptability of robots to different tasks but also improves the precision and efficiency of robots in performing complex actions. |  |

Fatigue resistance, cleanliness, low noise, increased productivity, and extended lifespanThe wear resistance of timing belts materials, low noise operation due to low-noise engagement with pulleys, and clean operation without the need for oiling are crucial characteristics. Robots often need to operate for long periods in industrial environments, and the low noise and clean operation without maintenance improve the comfort of the working environment and increase productivity with 24-hour continuous operation. The timing belts and pulleys produced by HERZ , using high-quality rubber materials, are manufactured through integrated processes including rubber refining, molding, vulcanization, grinding, and hot stamping, ensuring that the products meet the needs of industrial robots. |  |

Timing Belts – Key to Enhancing Robot Performance

Timing belts, as an underestimated component in robot transmission systems, play a crucial role in joint drive, motion mechanism, and end effector design.With advantages such as high-precision transmission, low-noise operation, and design flexibility, timing belts are irreplaceable in enhancing robot performance and efficiency. Zhejiang HERZ Transmission System Co., Ltd., as a professional manufacturer of transmission components, is committed to providing customers with high-quality timing belts and pulleys through continuous research and development innovation and superb belt drive manufacturing technology, contributing to the further development and application of robot technology.